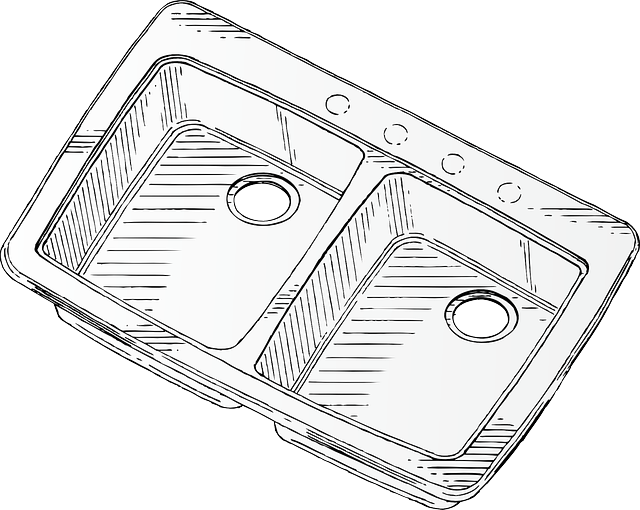

16 gauge? 20 gauge? 24 gauge? What does it mean? Which one’s the best stainless steel gauge thickness for my new kitchen sink? These are some of the questions you might have when choosing your next stainless steel kitchen sink. There are so many brands and styles from each manufacturer, and you want to make sure you make an informed choice. This article will focus on helping you decide on the thickness (gauge) of metal to shop for and to make the best choice for your situation. If you are finding it hard to decide then you may want to consult a professional plumber or sink installer beforehand for advice. This is also a good time to ask questions such as is it better to use a gauge that has been treated by a heat treating company beforehand? Or what type of metal should you be using specifically for your sink? It can be helpful to get these questions sorted out so you may get all the information you need to be sorted out before you need to make decisions.

- THE SHEET OF STAINLESS STEEL THAT IS USED DURING THE MANUFACTURING PROCESS IS ROLLED TO A SPECIFIC THICKNESS. SHEET METAL IS AVAILABLE AS FLAT PIECES OR AS A COILED STRIP. THE COILS ARE FORMED BY RUNNING A CONTINUOUS SHEET OF METAL THROUGH A ROLL SLITTER. THE THICKNESS OF THE SHEET METAL IS CALLED ITS GAUGE. THE GAUGE OF SHEET METAL RANGES FROM 30 GAUGE TO ABOUT 8

- MOST STAINLESS STEEL SINKS ARE MANUFACTURED USING A PROCESS CALLED DEEP DRAW FORMING WHERE A SHEET OF METAL IS DRAWN DOWN INTO A FORM THROUGH A SERIES OF STEPS CALLED REDUCTIONS. EACH REDUCTION STRETCHES THE SHEET METAL DEEPER AND DEEPER INTO THE FORM, SO WHAT STARTED OUT AS AN 18 GAUGE SHEET OF METAL WILL NOT END UP BEING 18 GAUGE THROUGHOUT THE ENTIRE FINISHED PRODUCT. THE INDUSTRY STANDARD IS TO STATE THE GAUGE OF THE METAL THAT THE MANUFACTURING PROCESS STARTED WITH.

- ZERO RADIUS SINKS ARE MANUFACTURED USING A PROCESS CALLED PRESS BRAKE FORMING WHERE THE SHEET METAL IS BENT INTO THE MAIN SINK SHAPE UNDER TREMENDOUS PRESSURE BY A MACHINE. THE SIDES ARE THEN ADDED AND WELDED TO THE MAIN ASSEMBLY, FORMING A BOX SHAPED SINK BASIN. ZERO RADIUS SINKS ARE IDENTIFIABLE BY THEIR FLAT SIDES AND UNIQUE 90 DEGREE OR NEAR 90 DEGREE CORNERS. SINCE THESE SINKS ARE BENT INTO SHAPE INSTEAD OF DRAWN, THEY RETAIN A MORE UNIFORM THICKNESS THROUGHOUT THE FINISHED PRODUCT.

The following table shows the actual thickness for popular gauges of kitchen sinks, as well as its density and % decrease in thickness compared to 16 stainless steel gauge, which is typically the heaviest gauge used for stainless steel kitchen sinks.

| Gauge | Decimal Inch | Millimeters | lb/ft2 | % Decrease in Thickness Over 16 Gauge |

| 16 | 0.0625″ | 1.5875 | 2.52 | – |

| 18 | 0.05″ | 1.27 | 2.016 | 20% |

| 20 | 0.0375″ | 0.9525 | 1.512 | 40% |

| 22 | 0.0312″ | 0.7925 | 1.26 | 50% |

| 24 | 0.0250″ | 0.635 | 1.08 | 60% |

On a side note if you ever need a carpet cleaning service, and you live in the beautiful Eureka CA area. Give A-1 Cleaning Service, LLC a call. They also perform carpet cleaning in Arcata Ca.

Stainless steels are iron alloys with a minimum of 10.5% chromium. Other alloying elements are added to enhance their structure and properties such as formability, strength and cryogenic toughness. These include metals such as:

- Nickel

- Molybdenum

- Titanium

- Copper

After a review of a large sample of key players in the kitchen sink market, including Blanco, Kraus and Houzer, the most common stainless steel alloy used in the manufacture of stainless steel kitchen sinks is 304 surgical grade stainless steel. The main elements added to the iron in 304 stainless steel are 17.5-20% Chromium (Cr) and 8-11% Nickel (Ni). Most sink manufacturers seem to choose 18% chromium and 10% nickel. With the rising costs of ferrochrome (used to make chromium) and shortages of nickel, one of the ways manufacturers control costs of kitchen sinks is to decrease the amount of material used. However, before you choose any type of kitchen sink for your home, ideally you should consult with a plumbing service provider such as Santa Clarita plumbing by City Plumbing and Rooter and choose the one that best meets your needs. The reason for this is that plumbers are generally familiar with all types of kitchen sinks and can recommend the best option for you. Once you’ve decided on a sink, you can have it installed right away.

So what should I look for in choosing a kitchen sink?

When shopping for a stainless steel kitchen sink, the number one thing to remember when assessing the thickness is: “The lower the number, the better.” Simply put, a lower gauge like 16 gauge is in most cases “superior” to a 24 gauge sink because it is thicker. How much thinner is a 24 gauge sink compared to a 16 gauge? Its only 40% as thick. A manufacturer can make a really cheap 22 or 24 stainless steel gauge sink because they are using 50-60% less material. Thinner sinks like this are usually seen as topmount or self-rimming and are easily found in big box stores, or maybe in your brand new home as a “contractor’s sink”. After you’ve decided on a kitchen sink, you should look for a reputable plumber who won’t undo all of your hard work. To find the nearest ones, you may search the internet for keywords such as plumbers Lynchburg or other places.

So why is thicker (lower gauge) better?

A lower gauge (thicker) sink is better for the following reasons:

- Improved noise dampening

- Less susceptibility to denting and bowing

- Strength and durability

It is generally agreed by sink experts that a heavier gauge can help prevent denting and bowing, and will also contribute to noise reduction from garbage disposals and items dropped or placed into the sink. Many sink manufacturers incorporate a sound proofing and insulation on the underside of the sink with coatings and/or pads. This will definitely help to make the sink quieter, but a thicker steel sink will have much better damping characteristics due to its mass.

What happens when you accidentally drop the pointy end of a butcher knife into the kitchen sink? Hopefully, nothing! A thicker kitchen sink will be less prone to dent and because it is stronger, it could make the difference between piercing the sheet metal, and not.

A thicker walled kitchen sink (lower stainless steel gauge) will bow less when you suddenly drain the water from a pot on the stove because the sheet metal is stiffer and will be more able to resist thermal expansion and movement.There is also less tendency for that Pop! sound when the boiling water hits the bottom of the sink.

Does a thicker (lower gauge) mean a better quality kitchen sink?

No, not necessarily. There is inherent better quality in the noise damping and structural integrity of the sink, however there are many other features which are probably more important in assessing the quality of a sink like finish, straightness and consistency. A stronger kitchen sink may also necessitate a better drainage system, as it can help prevent any leaks or clogs. Nevertheless, it could be smart to get a drain cleaning service for regular sink maintenance, just so that you can improve functionality and increase the lifespan of your kitchen sink system.

Is thicker always better?

Not necessarily for the sink manufacturer, since it is more difficult to “deep draw”, or craft from a single sheet, and to reduce welding marks on zero radius sinks. Depending on the complexity of the sink shape and its method of manufacture, optimal gauge thickness of 16 or 18 gauge will be used to balance cost with ease of manufacture and marketing.

So what stainless steel gauge should I buy?

The maximum gauge I would recommend for any stainless steel kitchen sink is 18 gauge. The best choice is of course 16 gauge, however either 16 or 18 gauge will provide the same top value in terms of cost, performance and overall satisfaction. Don’t bother with higher gauges (20, 22, 24) which are significantly thinner. My extensive market analysis shows there is no truth to the myth that the lowest gauge sinks are the most expensive – 16 and 18 gauge sinks are similarly priced.

18 Gauge vs 16 Gauge Sink?

If you had the choice between two identical sinks (16 and 18 gauge) at similar prices, don’t hesitate in getting the 16 gauge sink. Why? A 16 gauge sink is 0.0625″ thick, while an 18 gauge sink is 0.05″ thick, which is only 20% less. There is no noticeable difference between the two gauges, however at the same price range, 16 gauge is “better” (thicker is better!).

If you had two identical sinks, one 16 gauge and the other 18 gauge, but the 16 gauge sink was much more expensive, I would recommend the 18 stainless steel gauge sink, because of the incremental benefits.

Conclusion

In summary, just remember a lower numbered stainless steel gauge is better (thicker is better). The best gauge for stainless steel sinks is 16 gauge if available and the price range is acceptable, however don’t exclude 18 gauge sinks from your selections – either one is great value! The stainless steel kitchen sink is used many times a day and in so many ways. Paying attention to the non-functional requirements as well as the functional requirements will provide many years of satisfaction and pride. Every kitchen deserves a great sink.

Remember for the best Carpet Cleaning Service In Eureka, Ca, give us A-1 Cleaning Service, LLC a Call.

Most manufacturers use AISI 302 or 304 stainless (18Cr-8Ni). If welding is involved, this should be changed to a low carbon grade (ie. 304L) or to a stabilized grade (ie. 321 or similar grades where small amounts of tantalum or titanium are added) to prevent carbide precipitation in the grain boundaries. Failure to do this will cause the welds and heat affected zones to be chromium deficient and these areas may actually eventually rust! Grades 316 and 316L (18Cr-10Ni-2.5Mo) are far superior to 302 and 304 grades in terms of corrosion resistance.

Also, keep in mind that deep drawn sinks will NOT have a uniform thickness throughout! Certain areas may be thinned out considerably during the manufacturing process.

Great advise! My wife and I were wondering about getting a new kitchen sink and could not think of the options and which would be better. Thank you!